Stationary catalytic systems market is estimated to reach US$ XX Mn by 2026 in terms of revenue at CAGR of XX % in the forecasting Period. Regulatory norms toward industrial emission together with growing concerns related to GHG emission will drive the global stationary catalytic systems market. In the U.S., various regulations are being implemented towards industrial emission including National Ambient Air Quality Standards (NAAQS) that has been imposed on industries to regulate the industrial pollutant emissions. Coal-fired boiler replacement program in China will foster the industry growth during the current forecast period. In 2012, China has retrofitted 400,000 MW of existing coal-fired boilers with selective catalytic reduction. Since the average life of the catalyst is around 3 to 5 years. So, it has been analysed that it will positively encourage the replacement of the catalytic system in 2017. Increasing adoption of oxidation catalysts to control pollutant emission from gas turbine power generators is anticipated to drive stationary catalytic systems market in future. Additionally, wide application of catalytic incineration process at chemical, refining, metal and food industry in Asia will further complement the industry growth in future. Increasing demand for electricity along with growing population and rapid industrialization is set to drive the stationary catalytic systems market in upcoming years.  Stationary catalytic systems market is majorly segmented by the technology, application and region. Based on the technology segment, stationary is expected to have the higher growth rate in the current forecast period of 2018-2026. It is used to oxidize volatile organic compound from solvent evaporation by using metal oxides such as copper oxide, chromium oxide, nickel oxide and manganese dioxide. It has wide application in resin production, organic chemicals production and rubber & polymers production. Under applications segment, chemical and petrochemical are expected to higher growth rate through 2026 owing to rising petrochemical product demand. In addition to this, increasing focus on infrastructure development mainly in developing countries will further stimulate the market growth where the cement industry applications have held over 5% of global stationary catalytic systems market share in 2015 itself. Asia-Pacific held the highest market share in 2017 and is expected to have the higher growth rate in the current forecast period. The growth rate is coupled with China stationary catalytic systems market. It is expected to see strong growth due to the presence of a large number of power plants. For example, as of 2016, a 200,000 MW of coal-fired power plant was under construction in China for boosting the power plant supply. Key player across the stationary catalytic systems industry are Johnson Matthey, DCL International Inc., BASF, and Babcock & Wilcox Enterprises. Major participants are investing heavily in the research and development sector to develop the new product which is expected to positively encourage the business growth.

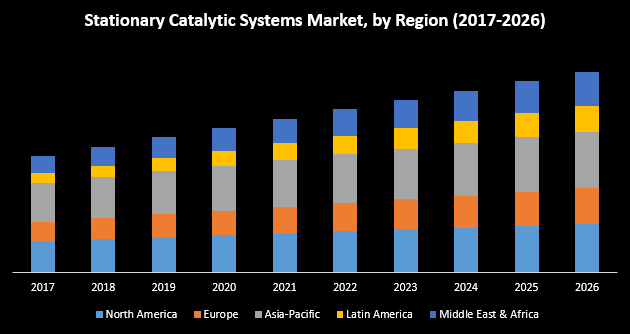

Stationary catalytic systems market is majorly segmented by the technology, application and region. Based on the technology segment, stationary is expected to have the higher growth rate in the current forecast period of 2018-2026. It is used to oxidize volatile organic compound from solvent evaporation by using metal oxides such as copper oxide, chromium oxide, nickel oxide and manganese dioxide. It has wide application in resin production, organic chemicals production and rubber & polymers production. Under applications segment, chemical and petrochemical are expected to higher growth rate through 2026 owing to rising petrochemical product demand. In addition to this, increasing focus on infrastructure development mainly in developing countries will further stimulate the market growth where the cement industry applications have held over 5% of global stationary catalytic systems market share in 2015 itself. Asia-Pacific held the highest market share in 2017 and is expected to have the higher growth rate in the current forecast period. The growth rate is coupled with China stationary catalytic systems market. It is expected to see strong growth due to the presence of a large number of power plants. For example, as of 2016, a 200,000 MW of coal-fired power plant was under construction in China for boosting the power plant supply. Key player across the stationary catalytic systems industry are Johnson Matthey, DCL International Inc., BASF, and Babcock & Wilcox Enterprises. Major participants are investing heavily in the research and development sector to develop the new product which is expected to positively encourage the business growth.

Stationary Catalytic Systems Market Scope

Stationary Catalytic Systems Market, By Technology

• Selective Catalytic Reduction • Catalytic Oxidation

Stationary Catalytic Systems Market, By Application

• Power Plants • Chemicals & Petrochemicals • Cement • Metal

Stationary Catalytic Systems Market, By Geography

• North America • Europe • Asia-Pacific • Middle East & Africa • Latin America

This Report Is Submitted By @Maximize Market Research Company

Customization of the report:

Maximize Market Research provides free personalized of reports as per your demand. This report can be personalized to meet your requirements. Get in touch with us and our sales team will guarantee provide you to get a report that suits your necessities.

About Maximize Market Research:

Maximize Market Research provides B2B and B2C research on 20,000 high growth emerging opportunities & technologies as well as threats to the companies across the Healthcare, Pharmaceuticals, Electronics & Communications, Internet of Things, Food and Beverages, Aerospace and Defense and other manufacturing sectors.

Contact info:

Name: Lumawant Godage

Organization: MAXIMIZE MARKET RESEARCH PVT. LTD.

Email: sales@maximizemarketresearch.com

Address: Omkar Heights, Sinhagad Road, Manik Baug, Vadgaon Bk,Pune, Maharashtra 411051, India.

Contact: +91 20 6630 3320/ +919607065656/ +919607195908